Hot Applied Bur Systems

WHY ROOF CONSTRUCTION

Roof Construction possesses a class C-39 Roofing Contractors license and has been applying Hot Process BUR Roofing Systems since 1992. Hire Experience!

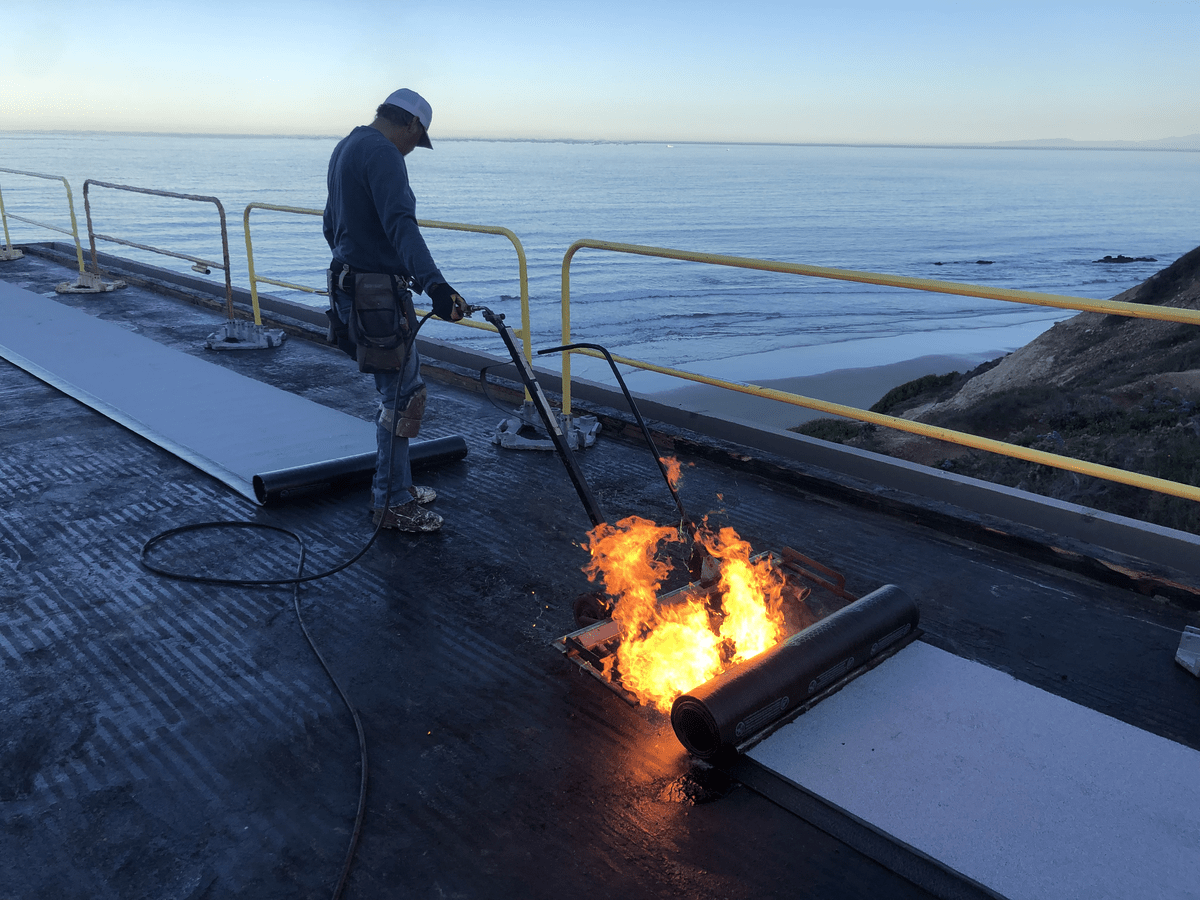

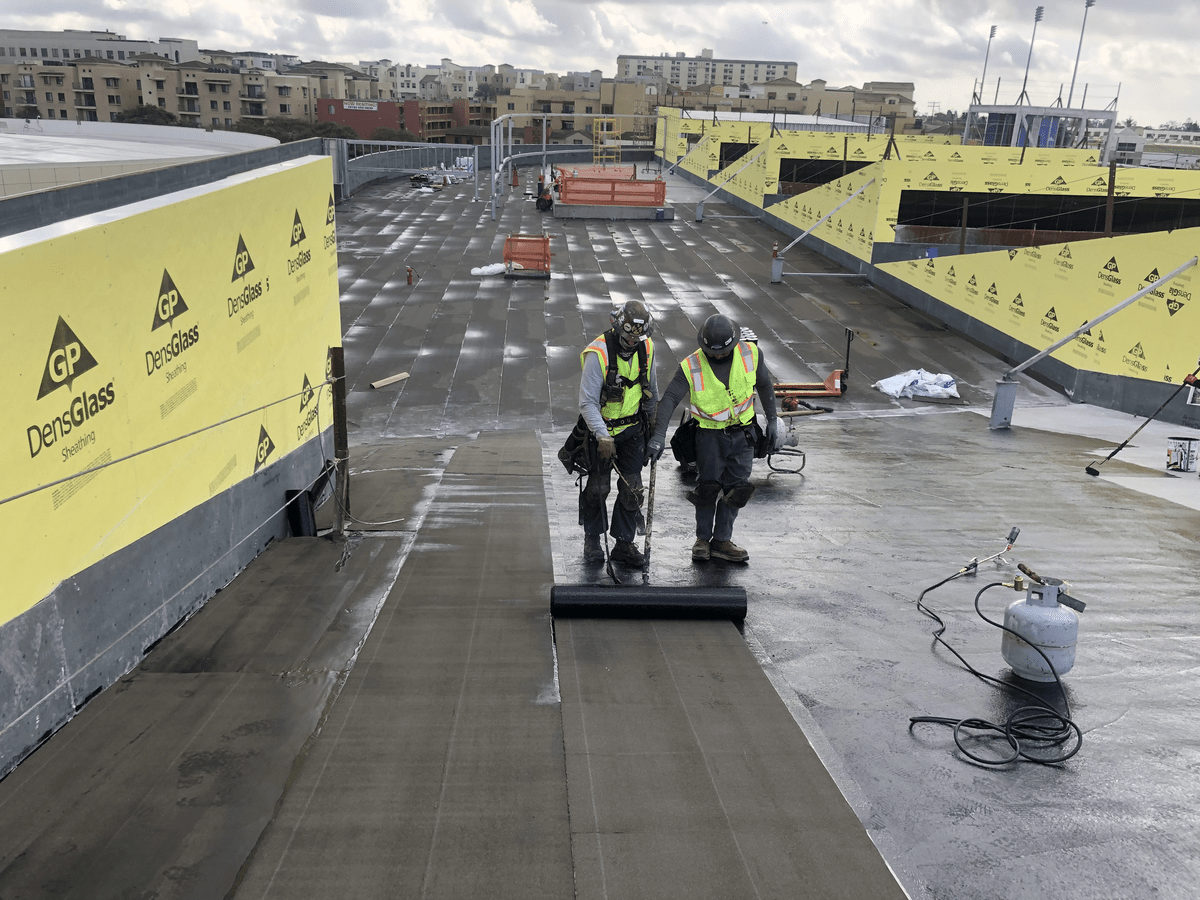

Hot Applied BUR and Torch Roofing Systems

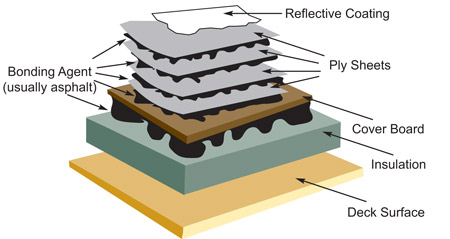

Traditional BUR (Built Up Roofing) System is a type of flat roofing system using layers of material made of tar and gravel, commonly referred to as “tar and gravel” roofs. This roofing system gets its name from the building of a roof using layers of base sheets, interply sheets and cap sheets or other surfacing such as gravel or liquid coating. Hot asphalt (bitumen) is the bonding and waterproofing agent that is applied between layers. BUR is suitable for most low slope roofing applications. The biggest drawback to BUR Roofing Systems is the smell of hot asphalt and the noise of the kettle.

The number of plies in a cross section is the number of plies on a roof: The term “four plies” denotes a four ply roof membrane construction. Sometimes, a base sheet, used as the bottommost ply, is mechanically fastened. Built up roofs generally are considered to be fully adhered if applied directly to roof decks or insulation.

Benefits of Hot Applied BUR and Torch Roofing Systems

- It’s one of the longer lasting types of flat roofing, easily lasting 20 years or more.

- It’s exceptionally durable and watertight roofing.

- The seams between membranes are melted together which prevent leaking.

- It has a high-tensile strength so they are unlikely to develop the kinds of cracks from weathering that other flat and membrane roofs experience.

- It’s easily adaptable to different roof slopes and designs.

Components of Hot Applied BUR Roofing Systems