Cold Process Bur Systems

WHY ROOF CONSTRUCTION

Roof Construction possesses a class C-39 Roofing Contractors license and has been applying Hot Process BUR Roofing Systems since 1992. Hire Experience!

Cold Process BUR & Coating Roofing Systems

One of the advantages of Cold Applied Roofing Systems over Hot Applied Systems is their ease of application. Very little equipment is required and just a few workers can complete the applications. Because there is no hot tar there is no need for the machinery for hot tar and no odor.

The cold systems can be applied as new or can be applied over existing smooth-surfaced roof systems. Although these roofs are waterproof immediately, they remain somewhat tender to roof traffic for 15 to 20 days, depending on weather conditions and system variations.

Cold-applied coatings also have some disadvantages. For instance, they have a slower adhesion development, so it is important to point out that, unlike hot roofs, there is a definite “set time” involved with cold-applied membranes.

Benefits of Cold Process BUR & Coating Roofing Systems

- It doesn’t give off the fumes that the hot applied BUR does, making it more environmentally friendly.

- It doesn’t need to be heated up during application, therefore doesn’t require the extra machinery.

- It’s a safer application compared to hot and torch-applied systems.

- Because it’s less labor-intensive than hot-applied systems the contractor is able to apply more squares in a shorter period of time.

- Lightweight cold-applied materials reduce the dead load on a roof.

- It’s easily adaptable to different roof slopes and designs.

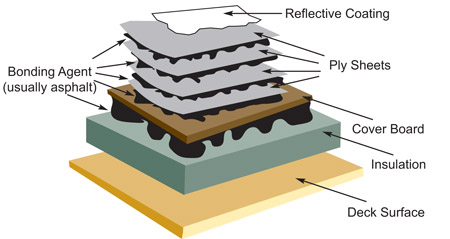

Components of Cold Process BUR Roofing Systems